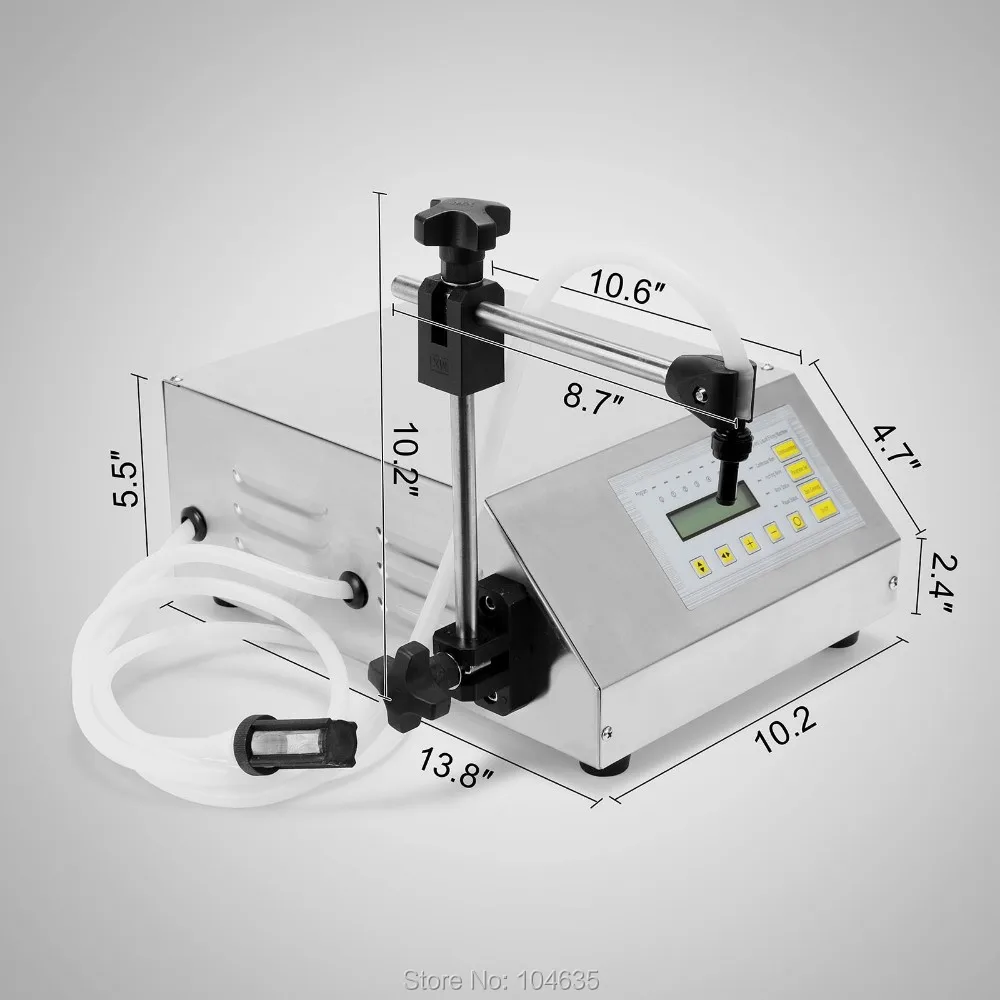

Digital control pump liquid filling and sealing machine

( 5-3500ml)

Introduction

Compact Digital Control Pump Liquid Filling Machine

Controled by micro-computer, fill liquid by setting the filling time and speed.

Filling Liquid From 5-3500ml very precisely.

Digital Panel, very easy to operate.

Characteristics

1. Import single-chip microcomputer control, high efficiency, low power consumption

2. Automatic counting function, effectively control filling quantiy

3. LCD display, touch screen is very easy to operate

4. High filing accuracy

5. Wide Voltage range

6. Working performance is stable and can be used for long time

7. This can self-suck the liquid.

8. The pump can stand acid and alkali

9. Anti-dripping design.

10. Reasonable design, made of stainless steel, meet GMP requirement

Parameter

Voltage AC 180V-260V (please leave us a message if you need 110V)

Power 30W

Filling Range 5ml-3500ml

Max Flow Rate 3.2L/min

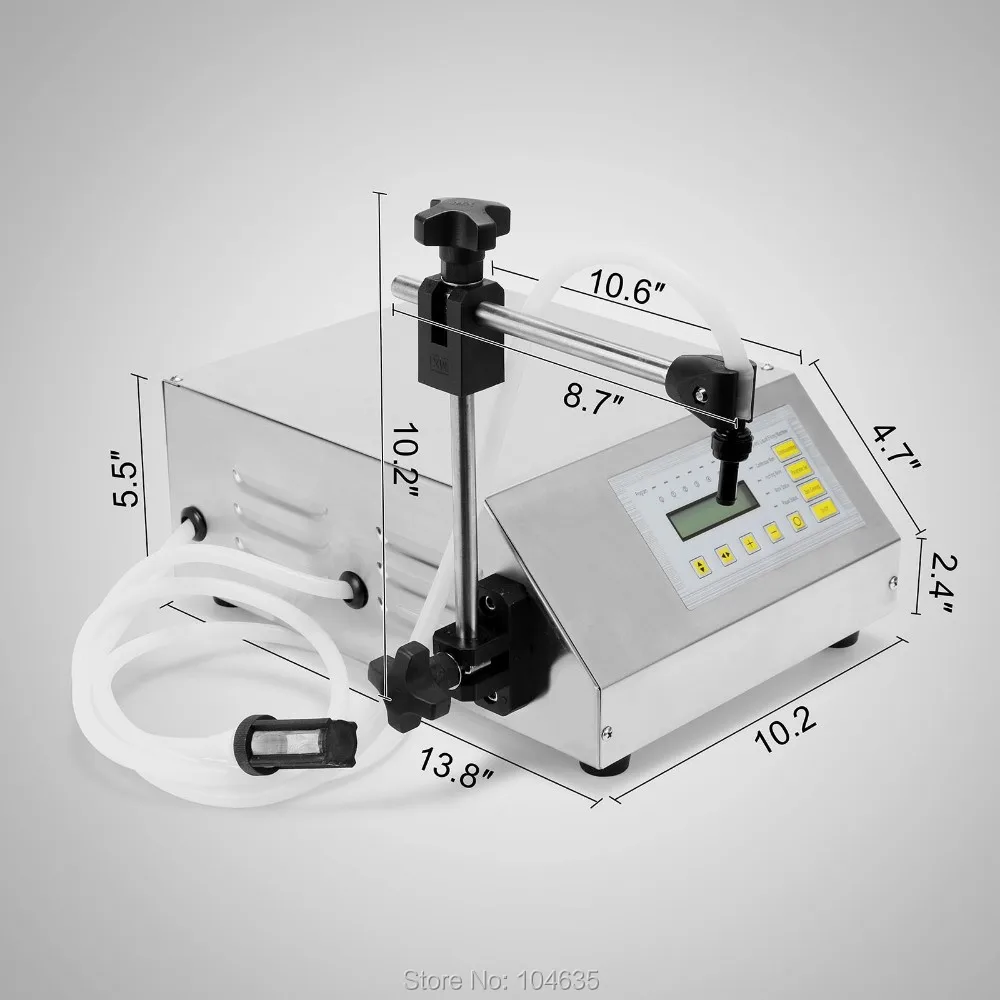

Package Size 400X380X200 (mm)

Weight 5.5kgs

Max Suck Distance 2meter

Anti-dripping Funtion Available

Memory Function out of power Available

Interior diameter of filling nozzle 5mm (if you ned smaller 3mm, please leave message with us.)

HOW TO USE

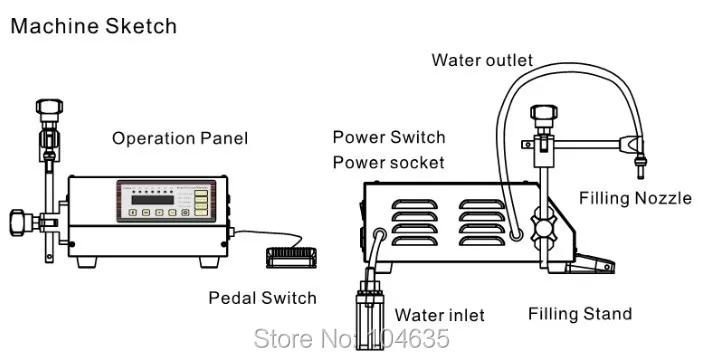

1. Installation

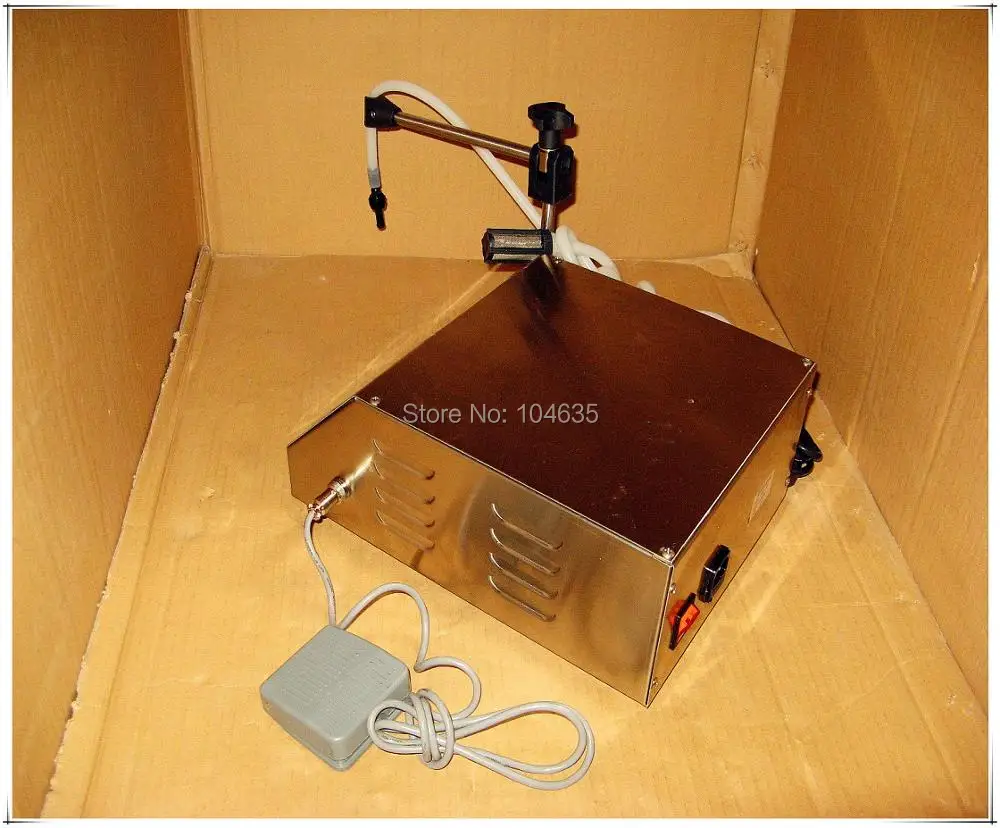

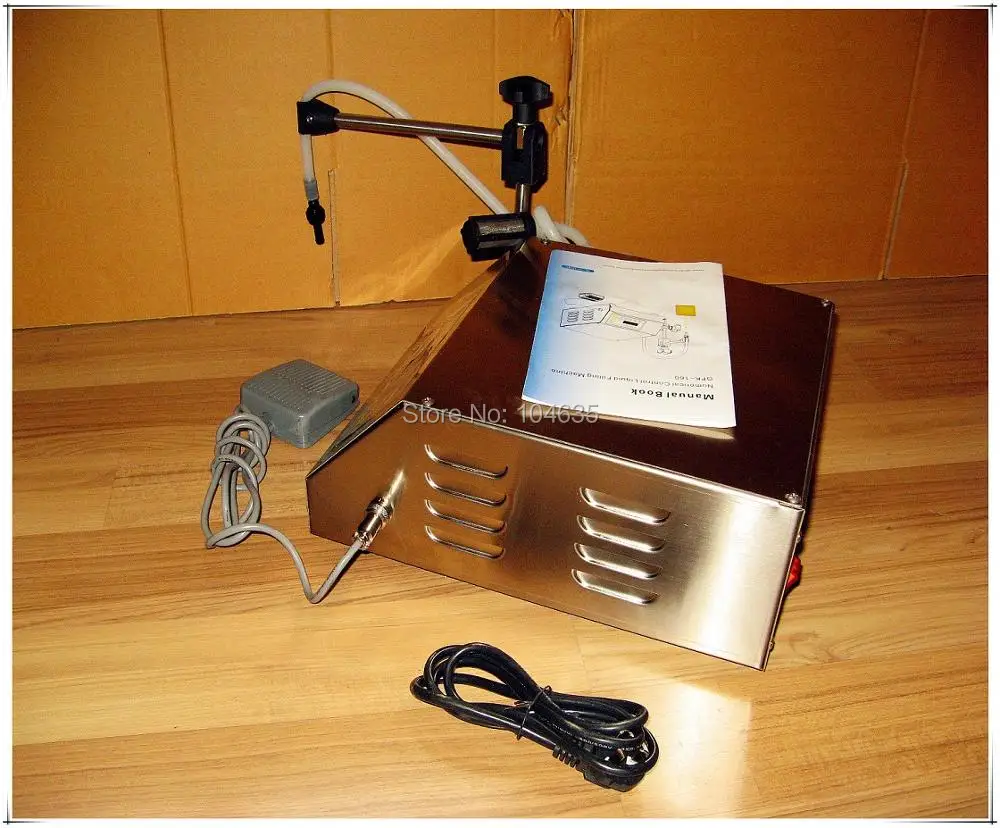

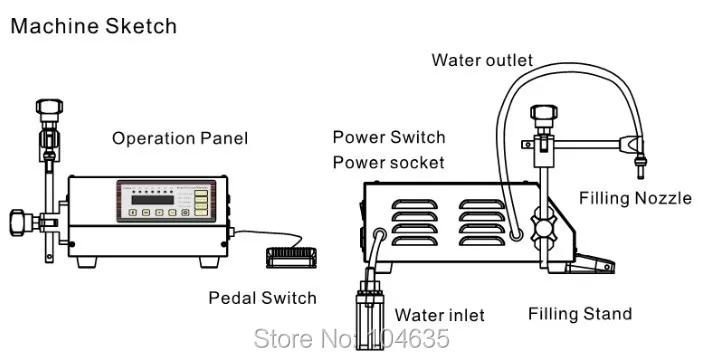

Take the plastic filling nozzle out and install it in the feeding tube. (Notice the triangle head connects the discharge tube). Take out the filling-head stand and install it on the left of the machines as photo3 shows. Put the filling head in the clip and tighten it by socket wrench.

Connect the pedal switch with machine, and put the tube with filter below the liquid level inside the storage rank. The position of tank should be lower than the machine. Start to test the machine after all is ready.

2. Turn on

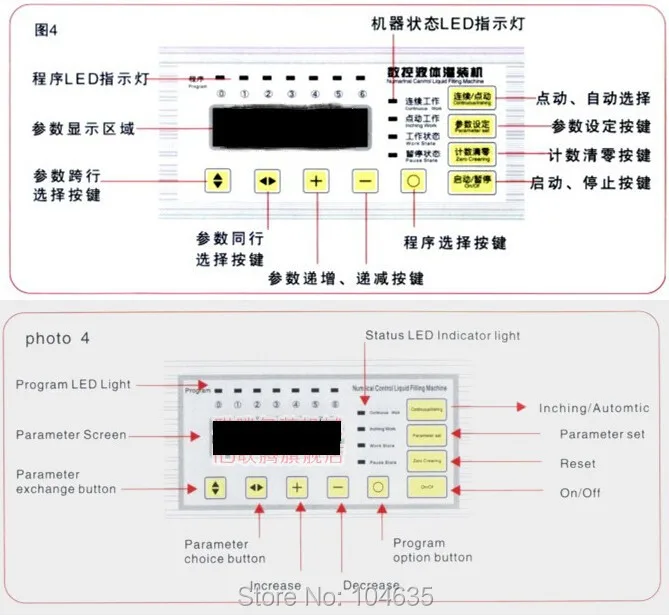

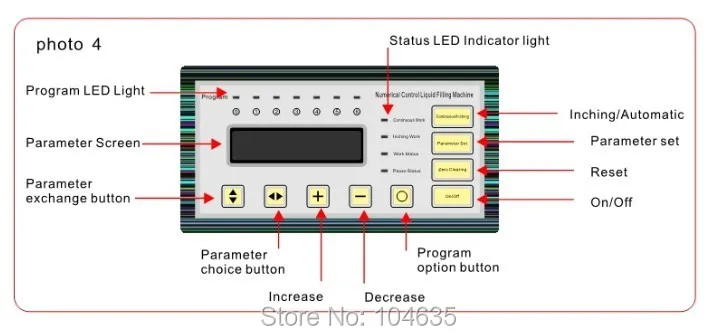

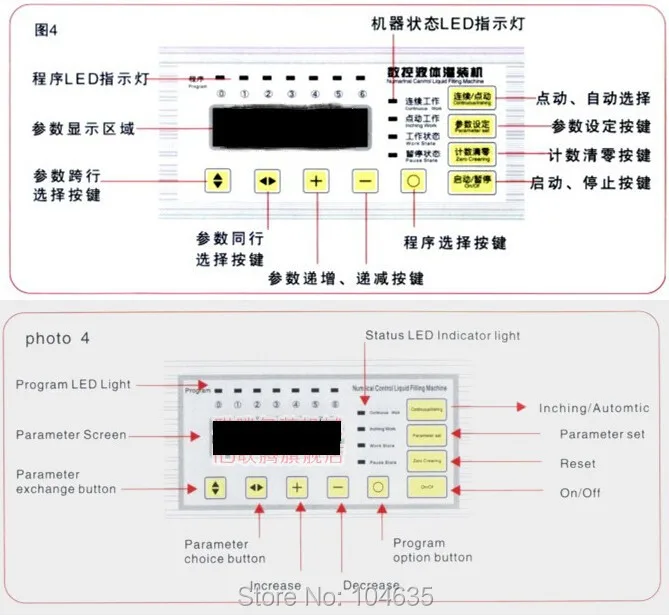

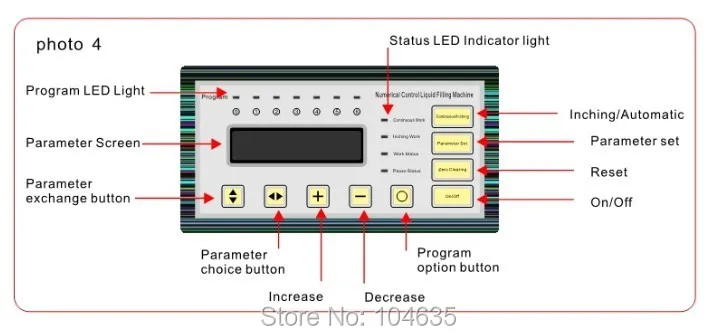

Switch on the machine, the LCD screen will show welcome words and the machine will be under standby status after 3 seconds. As photo4 shows, the screen shows filling quantity at the top left corner, filling speed at bottom left corner, once filling time at the top right corner, interval time at bottom right corner.

3. Adjustment

When the machine is under working status, other buttons can work. You can adjust the parameter after press the on/off button to let the machine under pause status.

4. Measurement Proofreading

This procedure is to check out if there is water coming out from the nozzle. By adjusting the filling time and speed to meet the requirement. The normal work can be carried out after the measurement proofreading is done.

Kindly note:The manufacturer will not be responsible for any damage due to improper operation. This kind of risk should be taken by the users. Strictly abiding by the manual book is a part of operation requirement.

Through our 24-hour emergency service and parts availability.

We are leading manufacturer & exporter of industrial Packaging Machines, Strapping Tools, Battery Powered Strapping Tools, Pneumatic and Manual Hand Tools, Embossing Machine, PET/ PP/ Steel Strapping, Vacuum Packing Machines, Filling Packing Machines Packaging Machine, etc.

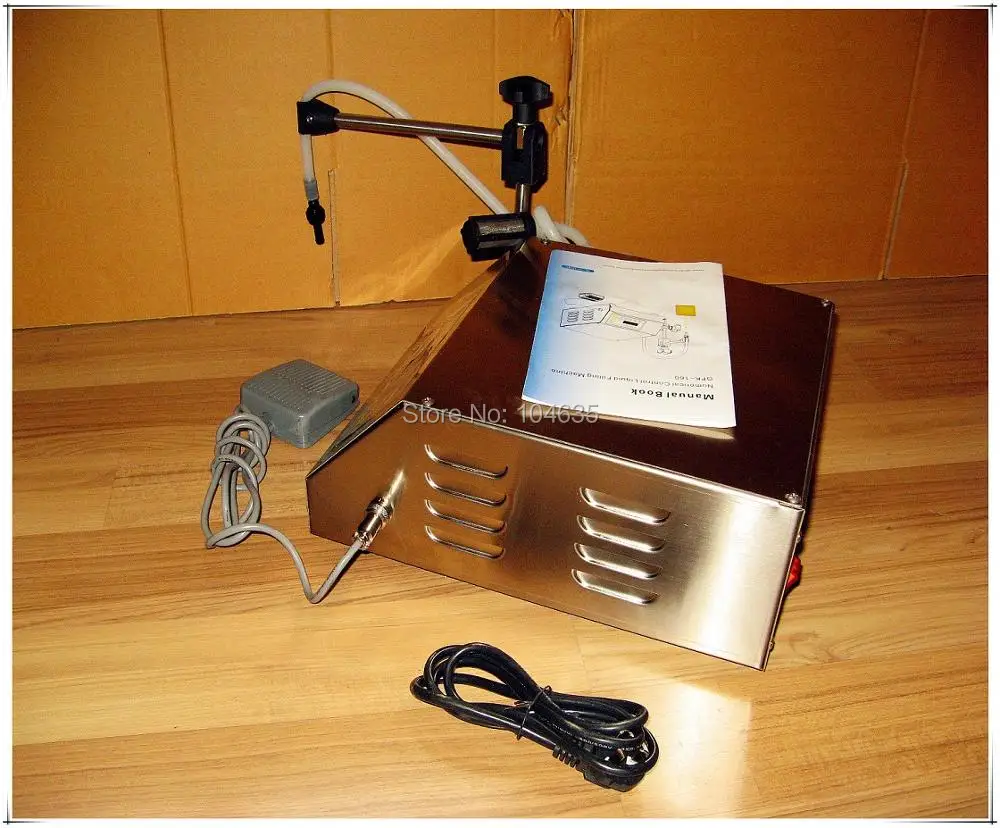

PACKING LIST

1.Power Cord 1pcs

2.Pedal Switch 1pcs

3.Filling Stand 1pcs

4.Filter 1pcs

5.Filling Nozzle 1pcs

6.Screwdriver 1pcs

7.Inner hexagonal wrench 1pcs

8.Manual Book 1pcs

9.Guarantee Receipt 1pcs

10.Quality Certificate 1pcs

strapping tool, steel strapping tool, pneumatic strapping tool, battery strapping tool, manual steel strapping tool, Wholesale, low price, china, factory, manufacturer, Sealing Machine, automatic sealing machine, continuous sealing machine, packing machine for food, heat sealing machine, automatic sealer machine, bag sealer machine, induction sealer, packaging machine, bottle sealing machine, aluminum foil sealing machine, cup sealing machine, automatic cup sealing machine, cup sealer machine, plastic cup sealing machine, capping machine, bubble tea cup sealing machine, cup Sealer